NOVO - Kennametal

NOVO™ is process knowledge delivered via the Machining Cloud™. It stands alongside such web-available solutions as MTConnect™ for data gathering and ISO 13399 for standardizing tool data. NOVO™ will utilize cloud functionality so everything is up-to-date, assuring users have access to the latest available tool information for process improvement.

Description

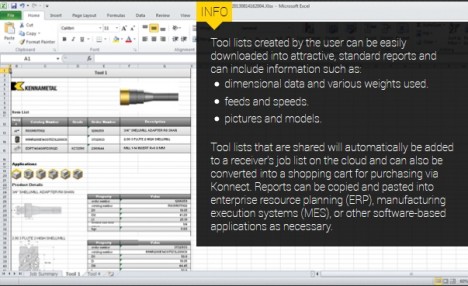

NOVO™ is an on-demand digital assistant with data-rich machining strategies that will optimize your productivity every step of the way — from parts quoting through programming, presetting, and production.

The TOOL ADVISOR is a rules engine application which provides cutting tool recommendations.

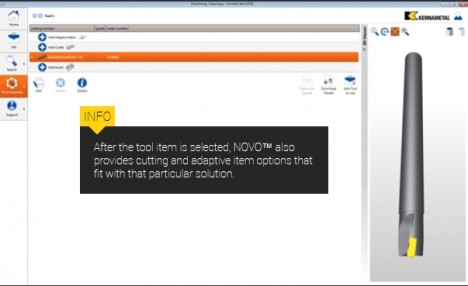

The TOOL SELECTOR provides the user with a method of selecting cutting tools from a tree structure using hierarchy / parametric search using fits-with / works-with technology.

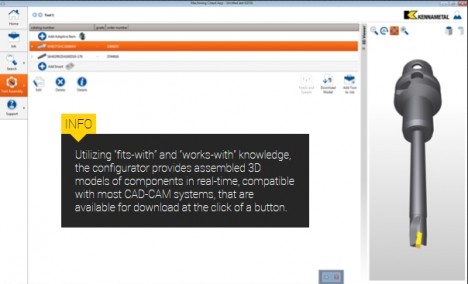

MoreIn both cases, NOVO’s™ TOOL CONFIGURATOR then provides all CAD files and graphic support for all tool components and their assembly – a major time savings for customers.

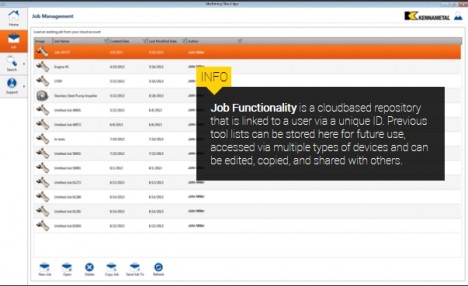

NOVO’s JOB FUNCTIONALITY stores all tool list and CAD files for future use.

For detailed information about NOVO from Kennametal, please click here.

Details

Updated: 08/11/2015Functionality: Aerospace/Defense, Automotive/High Performance, Construction/Farming, Oil/Energy, Fluid Power, Medical, Mold & Die, Wheel, Tooling

Compatibility:

- Works with Windows, iPad, Android

- No THINC API required

About The Developer

Chris LaufferCompany: Kennametal

Phone: 800.835.3668

Email: na-kmt.techsupport@kennametal.com

Kennametal was founded on the strength of a technological breakthrough, and a list of highlights demonstrates that it has continued to lead its industry in innovation. In 1946, the company introduced the Kendex line of mechanically held, indexable insert systems that accelerated tool changing and increased machining precision.

Kennametal's unique, patented thermit process for producing impact-resistant macrocrystalline tungsten carbide today remains the best way to produce extremely tough tool materials for demanding applications such as mining.

MoreIn 1964, Kennametal introduced tungsten-carbide-tipped Kengrip tire studs. Although studs clearly contributed to safe winter travel, they became controversial amid speculation about their role in road deterioration. After legislation limited the use of carbide studs, Kennametal left the business in 1977.

Leader in the development of silicon-nitride based "sialon" ceramics for the machining of exotic aerospace materials.

First to develop cobalt-enriched substrates for coated inserts, was first to commercially introduce physical-vapor-deposition (PVD) coated cemented carbide cutting tools and created the first commercially viable diamond-coated carbide inserts.

Leader in the development of quick-change tooling systems that today lead the world in versatility, speed and accuracy.

Kennametal maintains its technological leadership through its $30-million Technology Center at its world and North America headquarters in Latrobe, Pennsylvania, and complementary facilities in various locations around the globe. The facilities are dedicated to rapid development of products engineered to meet specific customer requirements.

Kennametal has been named a four-time best-practice partner for excellence in our world-class product development and portfolio management processes by the APQC, a non-profit organization and internationally recognized leader in benchmarking, knowledge management, measurement and quality programs.

App Feedback

For detailed information about NOVO from Kennametal, please click here.

Related Videos

Average Overall Rating

0 Reviews

0 Reviews

Comments

Interested In Being A Developer?

Are you interesting in becoming a developer? We'd love to hear from you!

Stay Informed

We'll keep you in the loop about new apps, events and other cool stuff.

Be the first to leave a comment